How To Field Strip M1 Garand

Field Strip your M1 Garand

Every M1 Garand should be stripped downwards, cleaned, and inspected before its initial employ. This step allows you to verify that the weapon is safe to shoot. While the weapon is apart, we'll audit the components and measure their state of wear. Your new M1 has likely been in storage for many decades. Prior to that, it may have seen service in several armies around the earth. A thorough inspection is the merely style to determine what status your M1 Garand is in.

Earlier outset, verify that your M1 is unloaded by pulling the op-rod handle fully back and inspecting the chamber!

Setup:

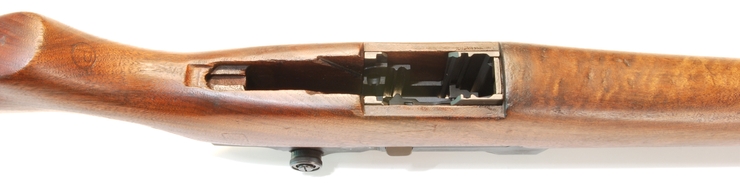

1 Lay your M1 Garand on its side with the muzzle facing towards your correct, Op-Rod handle facing up. The bolt should be closed with the safety on equally shown below.

2 If your M1 Garand has a sling attached remove information technology now.

3 Take hold of the trigger guard backside the trigger and pull toward the butt plate. This will unhook the trigger baby-sit latch and allow the trigger guard to pivot forrard.

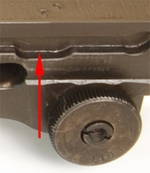

Sometimes the Trigger guard latch tin can be difficult to unhook. A piece of cleaning rod tin can assistance you in pulling back on the trigger baby-sit. The trigger latch hook can be seen in the image beneath.

iv With the trigger guard unlatched, rotate the trigger guard until information technology is fully open equally shown beneath.

5 With the trigger guard fully extended pull the trigger assembly direct out of the rifle.

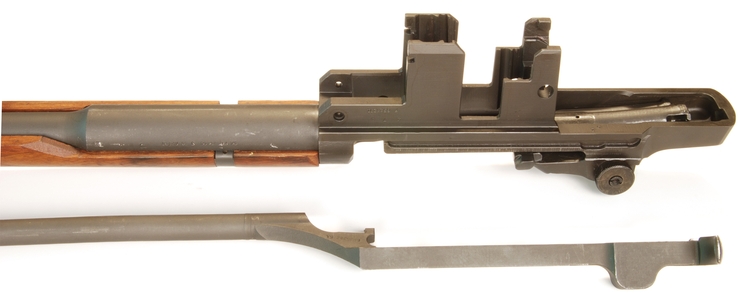

6 With the trigger assembly removed rotate your M1 Garand so the trigger associates well is facing up as shown below. Make sure your rear sight is lowered completely.

7 With your right hand hold the burglarize at the front handguard forrad of the sling swivel. Using the palm of your left hand elevator up on the stock left of the trigger. The stock will pin from the lower band and come up free of the receiver. If your stock has a tight fit you may have to physically pull the receiver out of the stock.

A tight stock fit may be the well-nigh important factor in achieving skillful accuracy potential with your M1 Garand.

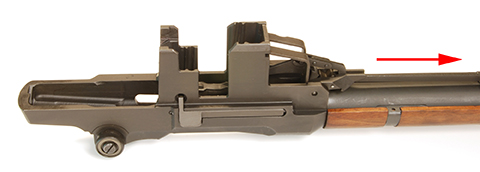

8 Compression the follower Rod with your pollex and index finger every bit indicated in the image below. With a firm concord pull the follower rod dorsum toward the muzzle compressing the op-rod spring and disconnecting the forks from the follower arm. When the forks are free you can lift up on the follower Rod and remove information technology and op-rod spring.

[Follower Rod]

nine Using a suitable tool, push out the Follower Arm Pin. A small-scale screwdriver or punch can be used.

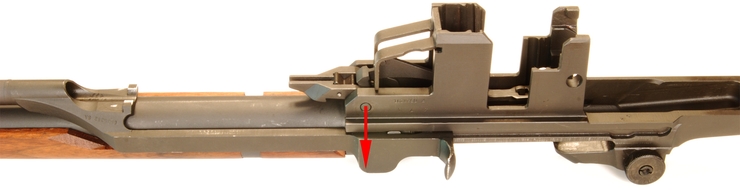

The Follower Arm Pin can only exist pushed out in the direction indicated below.

10 With the Pivot removed. Pull out the Op-Rod Catch. Before you do detect how the Op-Rod Take hold of arm hooks under the clip release lever arm. When reassembling the M1 Garand later you'll need to practice this before reinserting the Pin.

11 The bullet guide sits in ii notches in the receiver and should be removed toward the muzzle. Remove the follower arm at this time as well.

12 Accomplish into the receiver and remove the follower associates. Pay attending to the orientation of this function. On assembly, it's possible to get this put in upside down if one isn't careful.

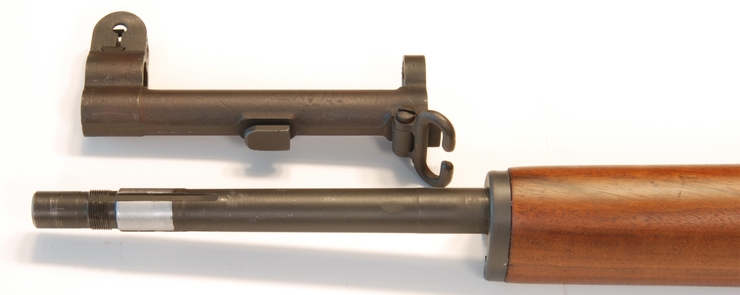

thirteen Slide the Op-Rod back until the Op-Rod tab is aligned with the notch cut in the receiver. When it is aligned with the notch gently push the Op-Rod handle toward the notch. This allows the tab to articulate the receiver channel. Gently pull the Op-Rod away from the receiver and rotate the Op-Rod handle. Slide information technology out from the Gas Cylinder.

NEVER force an Op-rod out of the burglarize. The rod can be aptitude causing accuracy bug and other failures. The OP-Rod has two bends in information technology. These bends tin can exist seen when looking at the Op-Rod from the side. Do not straighten your OP-Rod!

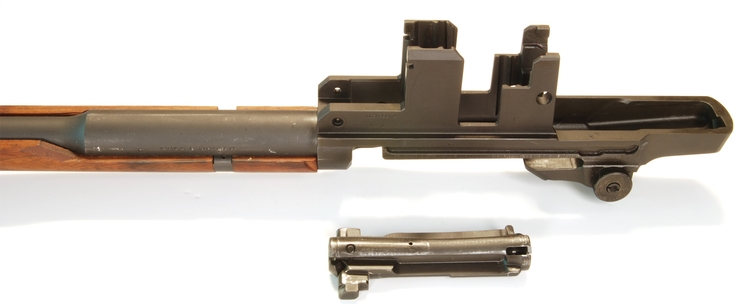

fourteen Slide the bolt forrard and let it driblet out of the receiver. Y'all may have to rotate the bolt so that the firing pin tang clears the notch in the receiver bridge.

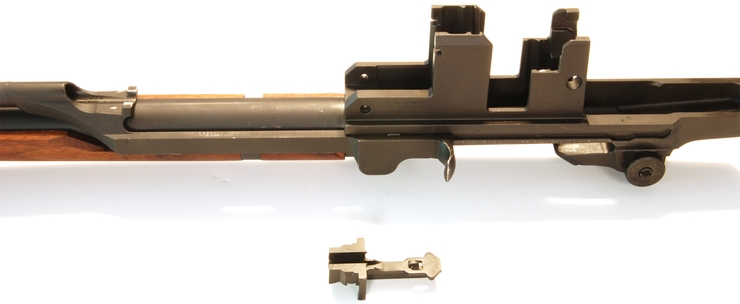

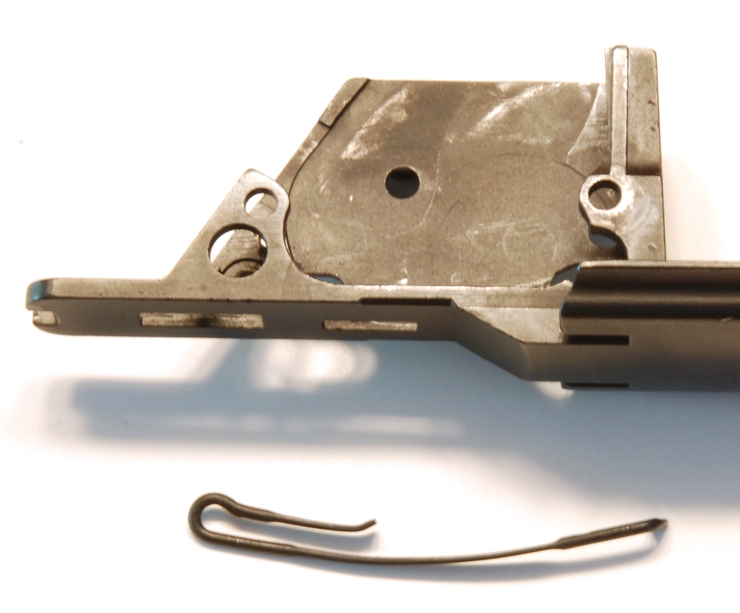

15 Lay the receiver on its side and printing out the prune latch pin in the direction shown beneath. The clip latch jump will want to bind the pin as you lot remove information technology. To forbid this, depress the prune latch with your thumb and remove the pin. One time the pivot has been removed the entire associates can be pulled costless from the receiver. When assembled the stock prevents this pin from sliding out during utilise.

The Prune Latch bound should exist replaced when bringing an M1 Garand back into service. A weak spring tin can cause clips to be ejected early during firing.

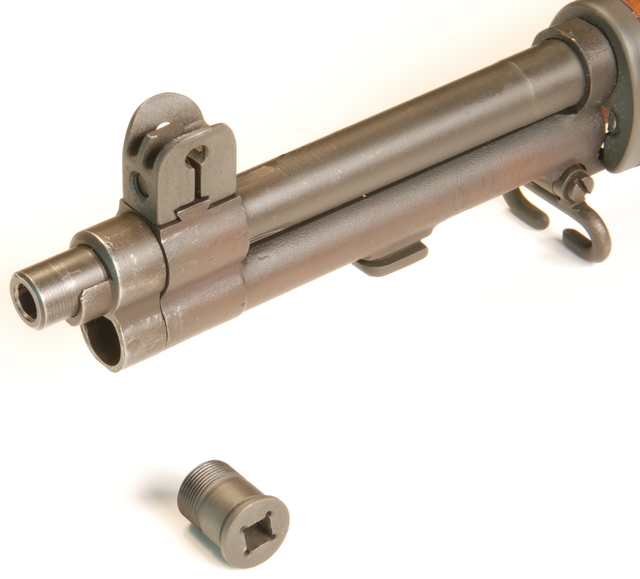

sixteen Using a Gas Cylinder Wrench [Product Link] support the gas cylinder and unscrew the Gas Plug from the gas cylinder. A Gas Wrench is an of import tool that prevents torque on the gas cylinder from transferring to the barrel splines. If the butt splines get loose, the accuracy of the weapon decreases significantly.

17 Unscrew the Gas Cylinder Lock Counter Clockwise when looking at the muzzle.

Finish hither if you lot are performing a once-a-year teardown and inspection. The post-obit steps should exist performed during your initial weapon inspection, but only minimally thereafter. Removing the Gas cylinder and lower band frequently tin can degrade accuracy by loosening their fit. Nosotros'll show you lot in another article how to tighten both if they're already loose.

Going all the way:

18 Slide the Gas Cylinder off the butt past pulling it toward the muzzle. If the Gas Cylinder will not slide off freely you tin tap on the bayonet lug to complimentary it.

19 Slide the Front handguard off by pulling it toward the muzzle. Be careful not to damage the wood at the interface to the Lower Ring.

Nosotros practise not recommend removing the front handguard ferrule and spacer unless damaged. These parts crave a special tool for re-installation.

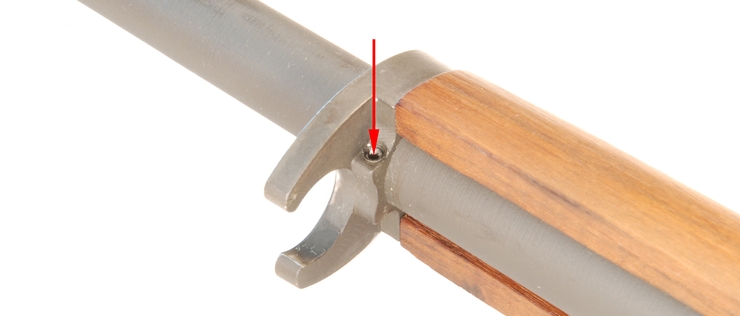

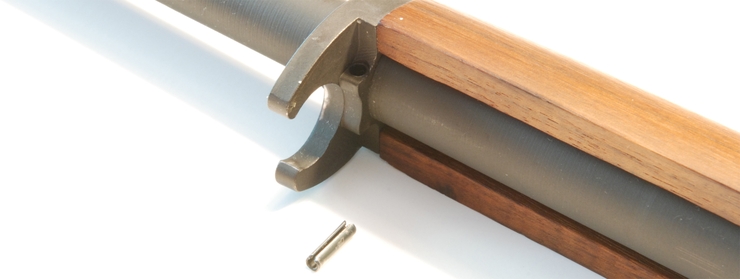

20 Place the M1 Garand on its side and locate the Lower Ring pin. This pivot holds the lower band onto the butt. This Pin tin be solid or the more common roll pin type. Inspect the lower band and determine if one end of the Lower ring has been peened over. Sometimes the lower ring pin can only be removed in one direction.

21 Using an appropriately sized punch tap out the lower band Pin.

22 Using a non-marring tool tap on the Lower band on the ledge nearest to the Lower band Pin and bulldoze the Lower band off the barrel.

23 Carefully grab the rear handguard and slide it forward toward the cage until the retaining clip slides free from its butt groove.

Exist very conscientious with the rear handguard and prune. The wood is very sparse and handguards crack very easily from mishandling. We do not recommend removing the rear handguard prune. The take chances to the handguard doesn't justify the attempt. The clip should merely exist removed if it's damaged or broken.

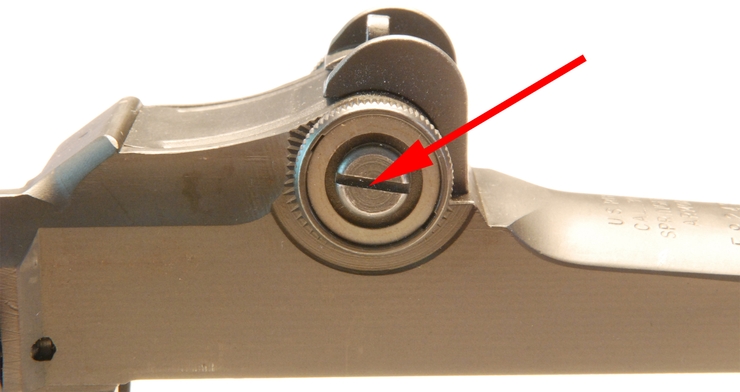

24 Rear Sight Removal. Start past grasping the peak knob on the left side of the receiver and make certain the screw is non loose. Use an appropriate-sized standard screwdriver and turn it clockwise to tighten.

The elevation knob will want to spin while you are tightening the screw. Hold the knob with your complimentary hand when tightening.

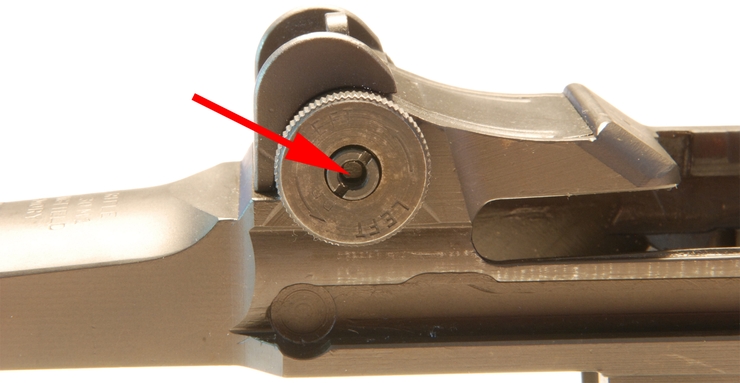

25 Using an appropriately sized standard screwdriver or the M1 Combination tool, turn the windage screw counterclockwise until it spins freely. The screw will remain captured in the knob when loose.

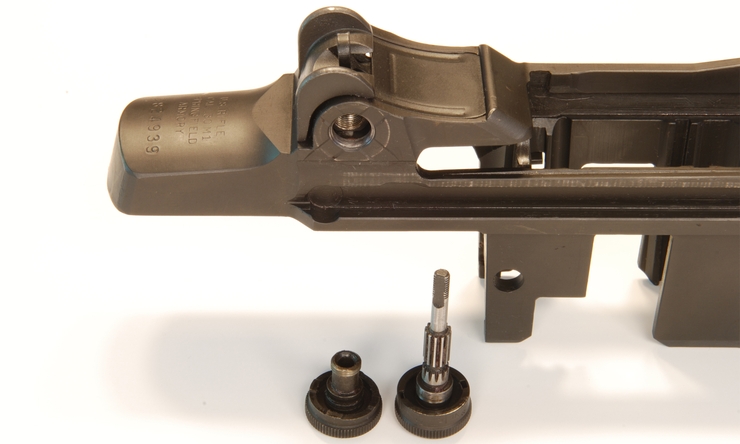

26 With the windage screw loose you tin can at present remove the knob. Hold the elevation knob with your gratis hand and unscrew the windage knob counterclockwise until it comes free from the sight.

27 Slide the elevation knob and shaft direct out of the receiver.

When y'all re-assemble the rear sight, apply a sparse coating of grease on the detents on the receiver where the knobs rotate. This will decrease the wear on the knobs and allow for a smooth sight adjustment.

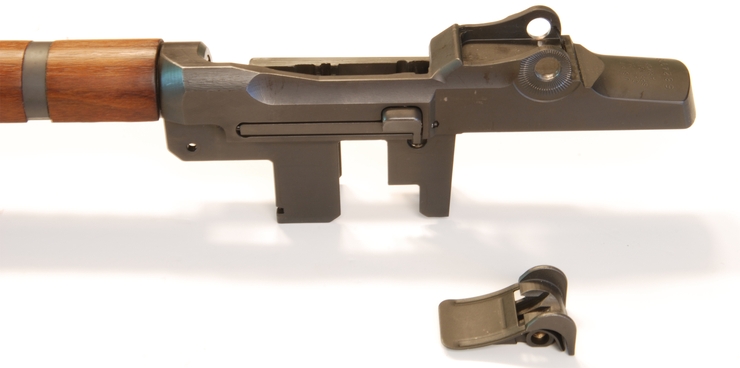

28 Grab the rear sight and slide it out of the receiver. Slide the rear sight base of operations dorsum towards the heel of the receiver as shown below.

29 Using a wide standard screwdriver gently pry up on the rear sight base of operations. This will cause the rear sight jump to pop out. Be sure to use a piece of material under the screwdriver to prevent it from marring the end on the receiver when prying.

Stripping the Stock and Handguards:

i Using a wide standard screwdriver unscrew the two screws on the base of operations of the butt plate and remove the buttplate from the stock. If the screws or the buttplate are stuck you can employ some rut from a hairdryer or heat gun to assist loosen them. Cosmoline tin can act equally an adhesive in some cases. All screws on the M1 Garand are standard right-hand threaded.

two To remove the retaining clip from the rear handguard requires the use of a special tool. Attempting to remove the handguard clip without the pliers will almost certainly consequence in damage to the handguard or the clip. This prune should never demand to exist removed unless it is broken or the woods is being refinished. We've included the step here for completeness just this should not be attempted E'er without the tool. Follow the instructions that come up with the tool to remove the prune.

iii The front handguard contains a spacer and the front handguard ferrule. These parts were never designed to be removed one time installed. The only reason to remove these is to refinish the wood or replace a broken part. These parts can be removed simply at some take chances to the wood and the parts themselves. To remove the spacer you accept to curve back the Tabs holding the ferrule on and slide out the spacer. However, bending the tabs often damages the parkerizing and work hardens the bend. A special tool needs to exist used to properly reinstall the spacer when finished. If you don't have the tools to do this stride properly nosotros recommend leaving on the parts. The ferrule can sometimes be wedged on so firmly that damage to the wood occurs upon removal. If the ferrule doesn't come up off by paw, leave it on. Forcing it damages the function and often mars the wood in the process. The Spacer tool used during the installation of the liner is shown beneath with the spacer and ferrule.

4 The Front Hinge and Stock Ferrule can be removed from the stock if the wood is going to be refinished or the office is damaged. A tight stock ferrule is important to maintaining accuracy potential. Exercise not remove the ferrule unless y'all accept to. On many M1 Garands, the screw property the ferrule on has been staked and cannot be removed without damaging the part. If the screw doesn't united nations-thread completely, get out it. If the screw tin exist removed then the swivel drops out and the ferrule tin be eased off the stock. The ear's on the ferrule when compressed cause a rib-similar characteristic to form on the wood this helps the ferrule to grip the stock. Forcing the ferrule off will strip the embossed ribs off the wood and loosen the fit. The ferrule should be slowly and carefully rocked off the stock.

Stripping the Trigger Associates:

End! The trigger assembly must be de-artsy earlier continuing. Release the safety and make certain the hammer has fallen.

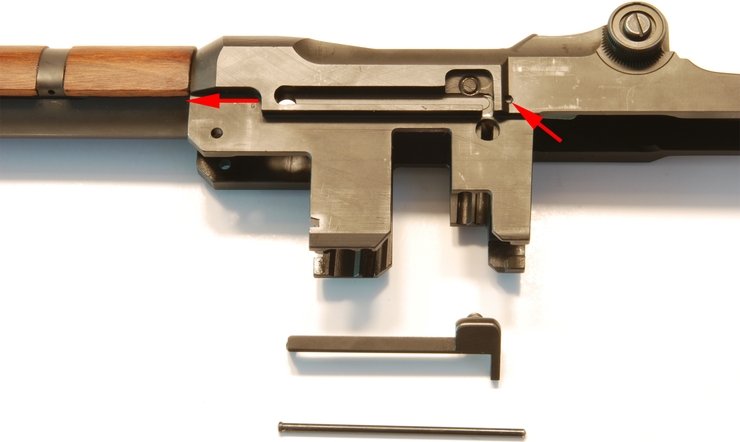

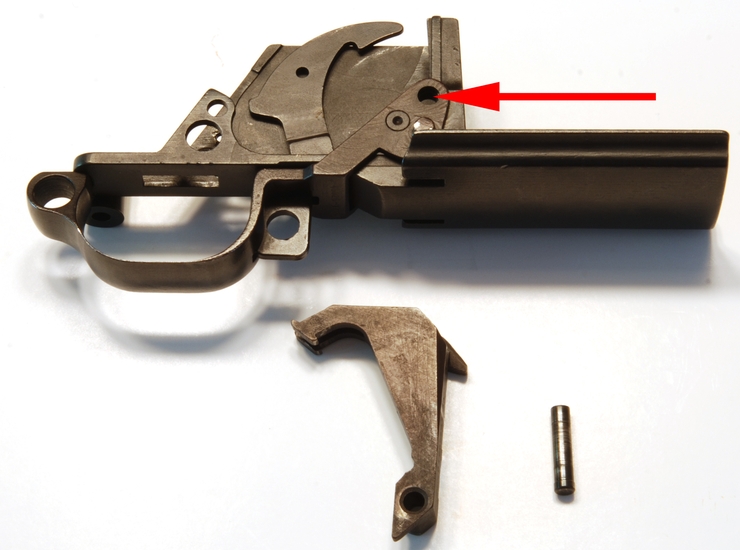

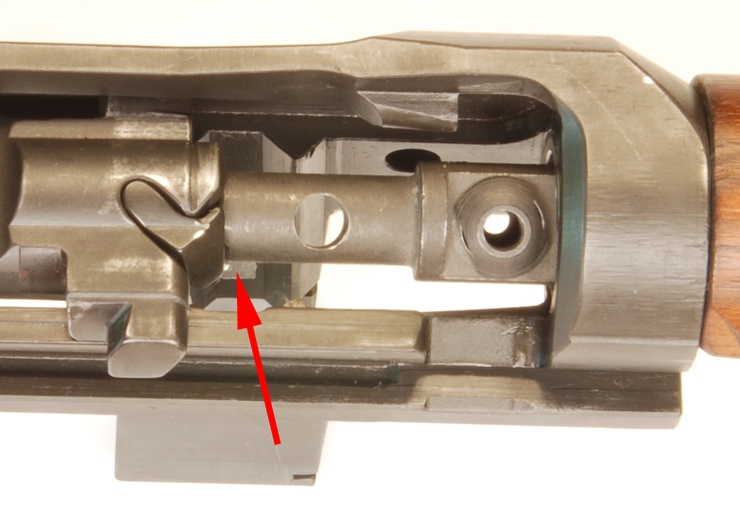

one The back of the sear must be supported when removing the trigger assembly pin. The hammer spring places considerable strength on this assembly. Failure to back up the sear tin can issue in parts existence ejected with considerable force. Put on a pair of safety glasses earlier continuing. The sear tin exist supported with your hand or a tool may exist used as shown beneath.

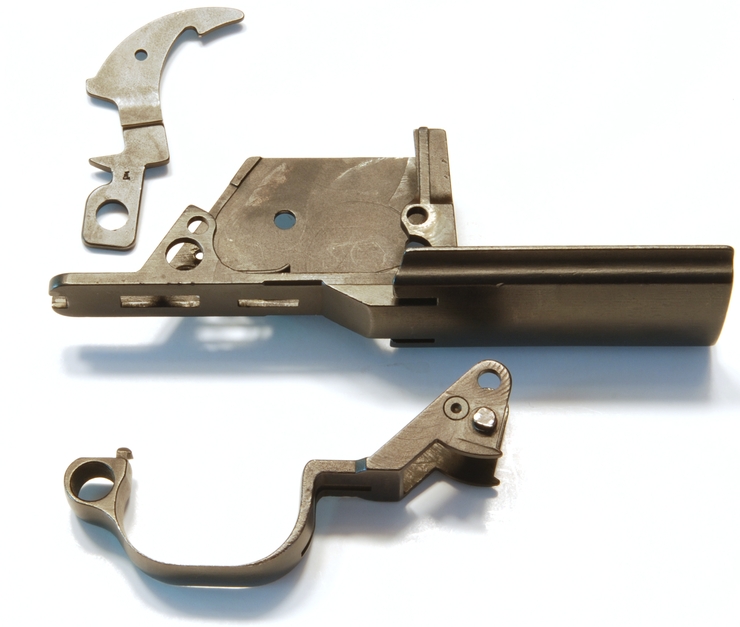

2 Using a punch press out the trigger pin (see paradigm above for location marked in red). This pin can but be removed in ane direction every bit shown by the arrow in the upper left image. This pin ofttimes pops out with considerable force. Be sure to have a backdrop that will take hold of the pin. With the pin removed, release your grip on the sear and allow the trigger spring to decompress. The photo below shows the right alignment of the sear, trigger, hammer, and spring assembly required during reassembly.

3 Remove the Sear/Trigger, Hammer Spring, Housing, and Plunger from the trigger assembly.

four Press out the Hammer Pin, freeing the trigger guard and hammer. This pin is removed in i direction just. One end of the pivot is larger in bore than the other.

5 Remove the safe by gently prying it from the trigger housing. The safe is snapped into identify with a small stud on its side. Next, remove the trigger baby-sit. Slide the guard aft slightly then rotate and pivot the part assuasive for its removal.

half dozen Using a non-marring tool button out the clip ejector spring.

There are several part assemblies that should not be broken down further. Those assemblies are the trigger/sear, windage knob, and follower assembly. There are no serviceable parts in these assemblies. The front end sight can be removed from the gas cylinder if it needs to be replaced. Moving the front end sight will effect the betoken of impact significantly.

Stripping the Commodities:

Finish! The bolt associates contains 2 springs compressed under significant force. E'er article of clothing centre protection when disassembling the bolt.

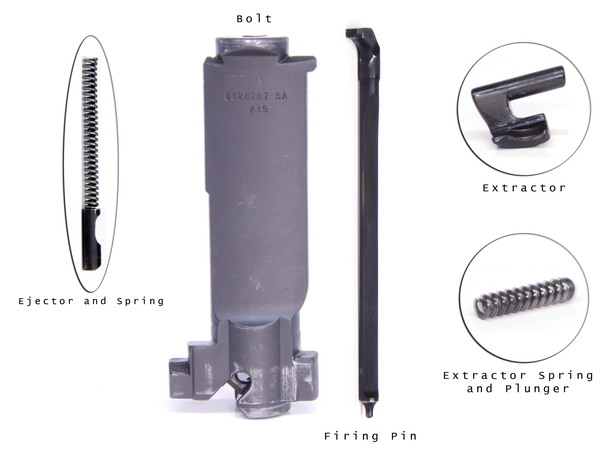

The bolt on the M1 can exist dissassembled past hand using the M10 multi-tool or with a bolt tool sold by the CMP. We'll testify y'all how to apply both. If you own several M1's and then the bolt tool becomes a time saver and makes the chore effortless. Shown below is an M1 bolt completely stripped with all its parts.

Using the CMP Bolt Tool:

one Lift the compression handle on the tool and insert the commodities. Orientation of the bolt should exist as shown below.

2 Using your left hand clasp the handle of the tool confronting the commodities causing the compression of the ejector and spring. With your right-hand press the extractor removal push on the bottom of the tool causing the extractor to exist pushed up from the commodities. Take hold of the extractor and remove information technology. Release the button.

Be sure to release the tool button earlier releasing the handle. If y'all fail to do this and so the tool button pivot will go pinched in bolt. Clasp the handle again and release the button pivot.

iii Release the handle and allow the ejector to decompress slowly and completely. Remove the bolt and pull out the extractor bound assembly and the ejector spring associates. The firing Pin slides straight out the dorsum of the commodities.

4 To re-assemble the bolt with the tool y'all demand to reverse the process. The most critical part is to brand sure the orientation of the ejector is correct allowing the extractor to snap back in place. Re-insert the firing pin, ejector assembly, and the extractor leap assembly into the bolt. Place the bolt back on the bolt tool and compress the ejector bound by squeezing the handle on the tool. Snap the extractor back into the bolt from the tiptop. When the extractor is seated you may release the handle of the tool.

Using the M10 Multi-Tool:

Use a thin layer of grease to the surfaces of the M10 tool that volition come up in contact with the bolt face up and butt shoulder. This volition reduce vesture on the end when the tool is rotated under load.

i retract the bolt and op-rod until it locks fully back. Insert the M10 tool into the chamber (Flat screwdriver end outset). Orient the tool such that the small lug on the M10 tool is nether the extractor (come across image beneath). Slowly release the bolt and ease it onto the tool. (Exercise Not SLAM the bolt onto the tool!).

(Op-Rod removed to show proper M10 tool alignment.)

2 Insert a segment of the cleaning rod into the hole in the M10 tool. This volition be the lever arm allowing you to rotate the tool and remove the extractor.

iii Loving cup your left mitt over the elevation of the bolt to catch the extractor as information technology pops out. Push the OP-Rod forward holding the bolt confronting the tool and rotate the M10 tool counterclockwise until the tool lifts up the extractor. The extractor may pop out with some force.

4 Slowly pull back on the bolt and remove the extractor spring plunger assembly and the ejector assembly. The firing pivot can as well at present be removed from the bolt.

v To re-assemble the bolt, install the firing pin, ejector associates, and extractor spring and plunger assembly back into the commodities. Verify the orientation of the ejector is correct before continuing.

6 Rotate the M10 tool back to its original position. Push the op-rod forward causing the ejector spring to shrink. With the ejector leap compressed printing the extractor dorsum into position.

seven Retract the bolt fully and remove the M10 tool from the rifle.

Congratulations!

You've just successfully performed a detailed strip of your M1 Garand. To re-gather your M1 Garand follow these instructions in opposite. Before y'all do be sure to read the section on role cleaning, inspection, and Improvements. You'll desire to read the section on lubrication before re-assembling the rifle.

Welcome to our new website. Returning customers will need to create a new account when checking out or use the guest checkout choice. -Eric Dismiss

Source: https://www.garandgear.com/m1-garand-strip/

0 Response to "How To Field Strip M1 Garand"

Post a Comment